Stainless Steel Hose Pipes

Stainless Steel Hose Pipes

The Stainless Steel Corrugated Hoses are available in stainless steel grades (AISI) 321, 316, 316L, & 304 by forming consolution so that it may conveniently bend while remaining liquid and gas tight. The hoses of specific length as per requirement can be manufactured with the end fittings in Flanged / Threaded types. The Flexible Hose are available in braidings of Stainless Steel wire to take care of external damage and to increase pressure ratings.

Flexibility Grades :-

i) Standard Pitch Tubing with Class 'B' flexibility as per BS part -1: 2004 / ISO 10380 : 2003. Common applications include fluid transfer for process industries, oil burners, misalignments.

ii) Fine Pitch Hose (Tubing) with maximum flexibility similar to Class C flexibility of BS part -1: 2004 / ISO 10380 : 2003. These are used for the most ardour flexing or high frequency at high temperature and high pressures. The pitch of the hose can be varied to achieve a range of flexibility and pressure rating as required for various application.

Advantages of Flexible Metal Hose

we have comprehensive testing facilities as per BS 6501- Part 1 as well as ISO 10380 standards. Following type of test carrying out at our works:

Flexibility Grades :-

i) Standard Pitch Tubing with Class 'B' flexibility as per BS part -1: 2004 / ISO 10380 : 2003. Common applications include fluid transfer for process industries, oil burners, misalignments.

ii) Fine Pitch Hose (Tubing) with maximum flexibility similar to Class C flexibility of BS part -1: 2004 / ISO 10380 : 2003. These are used for the most ardour flexing or high frequency at high temperature and high pressures. The pitch of the hose can be varied to achieve a range of flexibility and pressure rating as required for various application.

Advantages of Flexible Metal Hose

- Suitable for wide temperature range (-270°C to 700°C).

- It compensates for thermal expansion or contraction in piping system.

- High physical strength.

- Good corrosion characteristics.

- Fire resistant.

- Moisture resistant.

- Long life.

- Resistant to abrasion, penetration and damage.

- Absorbs or dampers vibration and noise from pumps, compressors, engines and similar Equipment.

- Connects misaligned rigid piping.

- Connects moving parts of machinery and equipment.

- Permits a very economical installation against rigid piping in difficult locations.

we have comprehensive testing facilities as per BS 6501- Part 1 as well as ISO 10380 standards. Following type of test carrying out at our works:

- Bend Test

- Flame Test

- Hydrostatic test

- Burst test

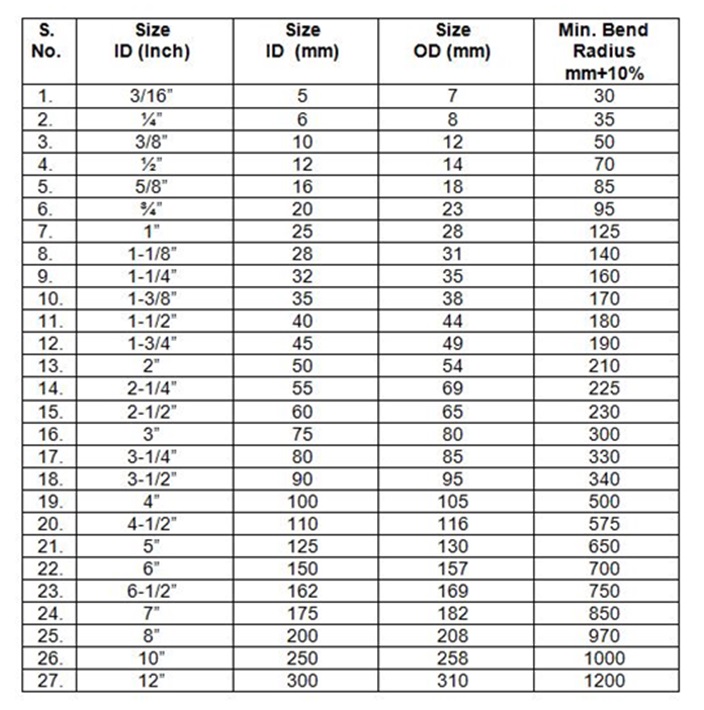

Hose Technical Data

Hose Technical Data| Nominal size N.B. |

Without braid pressure in kg/cm2 |

With Single braid pressure in kg/cm2 |

With double braid pressure in kg/cm2 |

|

|||||||||||||||

| Inch | mm | Max. working Pressure |

Test Pressure | Max. working Pressure |

Test Pressure |

Max. working Pressure |

Test Pressure |

Static mm |

Dynamic mm |

Static mm |

Dynamic mm |

||||||||

| 1/4" | 6 | 4 | 6 | 80 | 120 | 140 | 210 | 30 | 100 | 40 | 120 | ||||||||

| 3/8" | 10 | 4 | 6 | 70 | 105 | 125 | 180 | 40 | 150 | 50 | 160 | ||||||||

| 1/2" | 12 | 3 | 4.5 | 64 | 64 | 10 | 150 | 44 | 200 | 60 | 220 | ||||||||

| 5/8" | 16 | 3 | 4.5 | 66 | 90 | 90 | 135 | 56 | 200 | 60 | 220 | ||||||||

| 3/4" | 20 | 2 | 3 | 50 | 75 | 90 | 135 | 70 | 200 | 80 | 250 | ||||||||

| 1" | 25 | 2 | 3 | 50 | 75 | 80 | 120 | 90 | 200 | 100 | 260 | ||||||||

| 1-1/4" | 32 | 1.5 | 2.3 | 40 | 60 | 60 | 90 | 110 | 250 | 120 | 350 | ||||||||

| 1-1/2" | 40 | 1.5 | 2.3 | 32 | 50 | 50 | 75 | 130 | 260 | 160 | 400 | ||||||||

| 2" | 50 | 1 | 1.5 | 26 | 40 | 40 | 60 | 175 | 350 | 180 | 410 | ||||||||

| 2-1/2" | 65 | 1 | 1.5 | 20 | 30 | 32 | 50 | 200 | 410 | 200 | 450 | ||||||||

| 3" | 80 | 1 | 1.5 | 10 | 25 | 25 | 45 | 210 | 450 | 220 | 550 | ||||||||

| 4" | 100 | 0.8 | 1.2 | 14 | 21 | 20 | 30 | 230 | 560 | 260 | 660 | ||||||||

| 5" | 125 | 0.6 | 0.9 | 12 | 12 | 18 | 30 | 230 | 660 | 300 | 815 | ||||||||

| 6" | 150 | 0.6 | 0.9 | 10 | 15 | 15 | 25 | 320 | 815 | 420 | 1015 | ||||||||

| 8" | 200 | 0.5 | 0.75 | 10 | 15 | 15 | 25 | 410 | 1015 | 540 | 1220 | ||||||||

| 10" | 250 | 0.5 | 0.75 | 8 | 12 | 12 | 20 | 560 | 1220 | 620 | 1420 | ||||||||

| 12" | 300 | 0.3 | 0.45 | 6 | 9 | 10 | 15 | 660 | 1430 | 750 | 1650 | ||||||||

|

Note : » The above Technical details are subject to change without notice. » We can also supply the above Hoses for higher pressures. » The above values apply only to Braided Hoses and Assemblies at ambient temperature. |

|||||||||||||||||||

Braided Hose Pump Connector

Braided Hose Pump Connector

We manufactured various types of Stainless Steel Braided Flexible Pump Connectors.

Type - Stainless Steel Flexible Pump Connectors with Flanged End

Type - Stainless Steel Flexible Pump Connectors with Male Pipe Threaded / Hexagonal Male

Type - Stainless Steel Flexible Pump Connectors with Flanged End

| Hose Material | Braid Material | Hose Size | Hose Length Overall | End Fittings | End Fittings Material | Working Pressure | Offset Motion Static |

| Stainless Steel Aisi 304/321/316 | Stainless Steel AISI 304 Single/ Double | DN 25 (1" NB) To DN 300 (12" NB) | As Per Customer Requirements | Flanges Fixed /Floating CLASS #150 , 300 , PN10 , PN40 | CS / AISI 304 / 316/316L | 110 PSI To 510 PSI | 3/4" to 1/4" |

Type - Stainless Steel Flexible Pump Connectors with Male Pipe Threaded / Hexagonal Male

| Hose Material | Braid Material | Hose Size | Hose Length Overall | End Fittings | End Fittings Material | Working Pressure |

| Stainless Steel AISI304/321/316 | Stainless Steel AISI 304 Single/ Double | DN 12 (1/4" NB) To DN 100 (8" NB) | As Per Customer Requirements | Pipe End / Hex Male Fittings / BSP /BSPT /NPT | CS / AISI 304 / 316/ 316L | 230 PSI To 1800 PSI |

Interlock Hose

Interlock Hose

Stripwound Interlock Hose

Interlocked metal hose is also referred to as strip wound hose and consists of successive turns of profiled strip, with the edges of adjacent turns interlocked. Interlock Hoses are made with a packing so that filament of cotton, asbestos, rubber or metals like copper can be fed into the interlock to make it pressure tight. It is mostly used as a protective/conduit casing. It is also used as a liner inside the hose based on the profile formation.

Locking methods (Profile) are called :-

» Square lock

» Square lock

» Square lock with packing

» Double lock

» Double lock with packing

Applications :-

» As armour

» For telephone & electrical cables

» Control instruments & thermo couples

» For conveying non penetrating fluids such as tar, naptha, furnace oil.

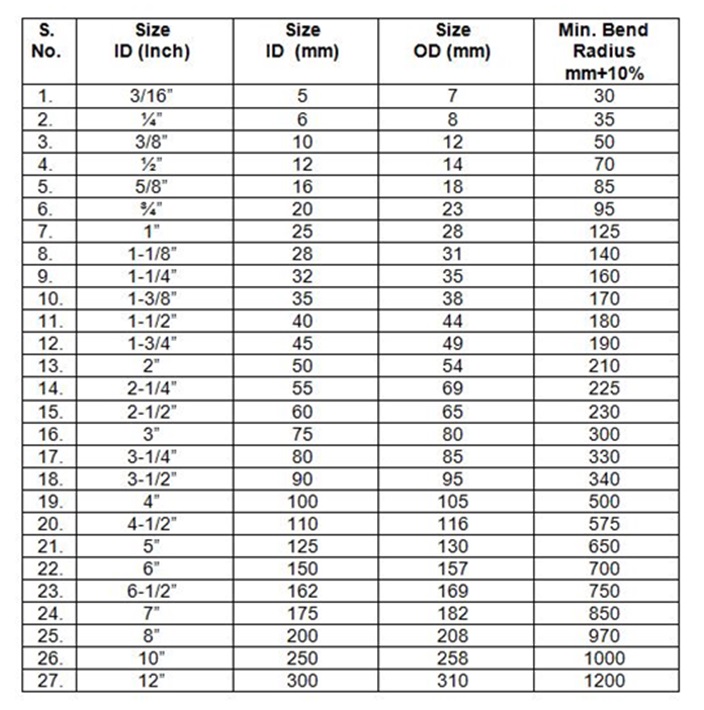

Size Ranges : DN6 MM (1/4¡± NB) TO DN 300MM (12¡± NB)

Material Grades : GALVANISED STEEL,STAINLESS STEEL SS 304 , SS316 , SS316L, SS202

Double Interlock Hoses :

Square Lock without Packing :

Interlocked metal hose is also referred to as strip wound hose and consists of successive turns of profiled strip, with the edges of adjacent turns interlocked. Interlock Hoses are made with a packing so that filament of cotton, asbestos, rubber or metals like copper can be fed into the interlock to make it pressure tight. It is mostly used as a protective/conduit casing. It is also used as a liner inside the hose based on the profile formation.

Locking methods (Profile) are called :-

» Square lock

» Square lock» Square lock with packing

» Double lock

» Double lock with packing

Applications :-

» As armour

» For telephone & electrical cables

» Control instruments & thermo couples

» For conveying non penetrating fluids such as tar, naptha, furnace oil.

Size Ranges : DN6 MM (1/4¡± NB) TO DN 300MM (12¡± NB)

Material Grades : GALVANISED STEEL,STAINLESS STEEL SS 304 , SS316 , SS316L, SS202

Double Interlock Hoses :

Square Lock without Packing :

Futuristic Software Consultancy

Futuristic Software Consultancy